Plastics & Fiberglass Tooling

High-Precision Plastics, Thermoforming, and Tooling — All Under One Roof

Your First Choice for Custom Plastic Manufacturing

Uniforce delivers engineered plastic components built for strength, accuracy, and consistent OEM performance. With in-house thermoforming, vacuum forming, custom tooling, CNC trimming, and precision finishing, we produce high-quality plastic parts designed for marine, automotive, off-road, industrial, and heavy-vehicle applications.

Our integrated processes allow us to move quickly from prototype to production while maintaining tight tolerances and exceptional surface quality. Whether you need deep-draw components, complex assemblies, or durable, cosmetically finished parts, Uniforce provides complete manufacturing control from start to finish.

Plastics Capabilities

- Thermoforming and vacuum forming for deep-draw components

- Large-format forming with consistent wall thickness

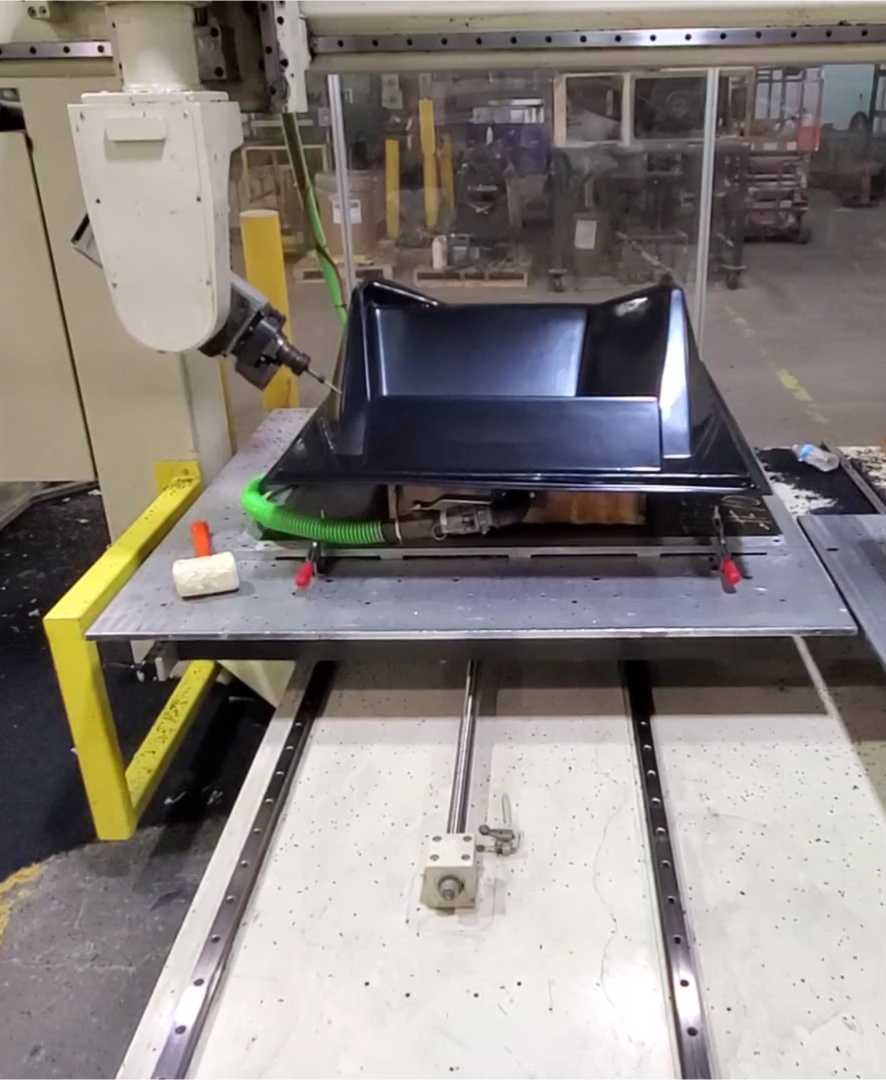

- Automated robotic cutting cells for accuracy

- 5-axis CNC machining for complex shapes and fine detailing

- Marine-grade, hand-wrapped vinyl finishes

- In-house fiberglass tooling for fast, precise production

Every part we manufacture is engineered to withstand real-world conditions, including UV exposure, vibration, moisture, and heavy use — making our components ideal for marine, off-road, and industrial environments.

Thermoforming & Vacuum Forming

Our thermoforming and vacuum forming processes allow us to create lightweight, durable, and cost-effective components with clean contours and consistent reproduction across every run.

Benefits of Our Thermoforming Process

- Ideal for mid- to high-volume production

- Capable of deep-draw and complex shapes

- Excellent repeatability and dimensional control

- Cost-effective alternative to injection molding

- Smooth, uniform surfaces for finished parts or wrapped components

With automated robotic trimming and CNC machining, every part is shaped with precision — ensuring that it fits flawlessly into your final assembly.

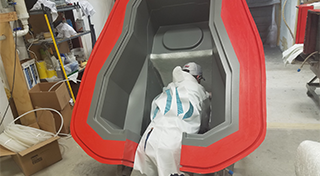

Fiberglass Tooling

Uniforce produces precision fiberglass tooling using a handmade, two-part process engineered for accuracy and durability. Our tooling supports complex geometries and allows for fast production, with typical lead times of 3–5 days for tool creation and ~2 weeks total for the complete process.

Advantages of Fiberglass Tooling

- Supports complex curves and deep-draw requirements

- Highly durable and long-lasting

- Ideal for thermoforming and vacuum forming applications

- Fast turnaround for prototypes and short-run production

- Lower cost compared to aluminum or steel tooling

Our tooling process ensures clean definition, reliable performance, and long-term stability across repeated production cycles.

Uniforce Composites

Read More ⇢

Uniforce Plastic

Read More ⇢

Uniforce Tech

Read More ⇢